Sustainable Materials in Car Interiors

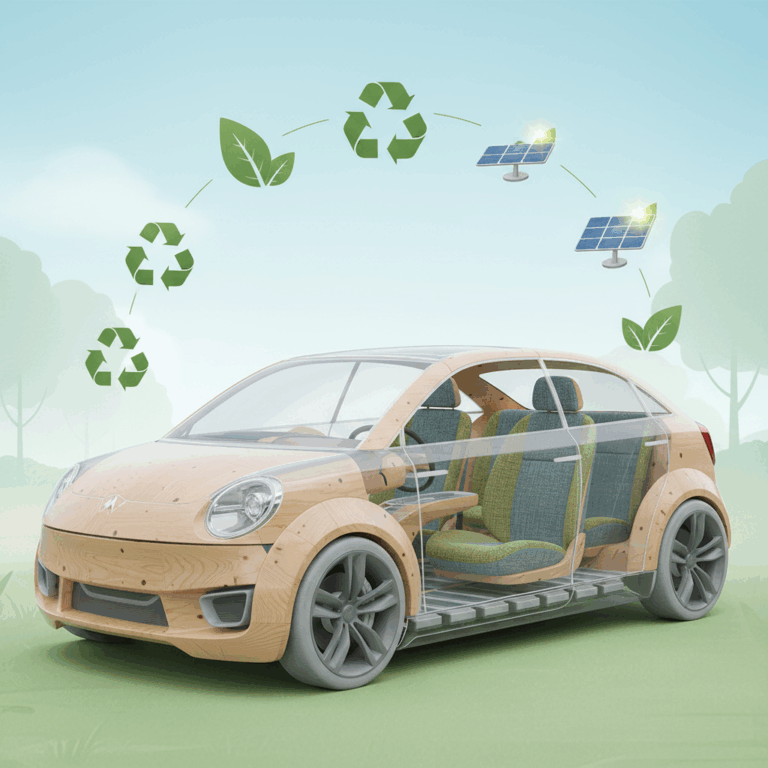

Car interiors are increasingly incorporating sustainable materials to reduce environmental impact and enhance vehicle durability. These innovations support eco-friendly automotive manufacturing.

Key materials like synthetic leathers and natural fiber reinforced plastics improve fuel efficiency by reducing vehicle weight while supporting greener production processes.

Synthetic Leathers like SofTex

Synthetic leathers such as SofTex offer an eco-conscious alternative to traditional leather by being lighter and generating fewer carbon emissions. This benefits both car performance and the environment.

These materials provide the luxurious feel of real leather without involving animal products, aligning with sustainability goals in modern vehicle interiors.

Additionally, SofTex enhances durability and requires less energy to produce, making it a smart choice for automakers seeking to reduce their carbon footprint.

Natural Fibers Reinforcing Plastics

Natural fibers like hemp, flax, kenaf, and coconut fiber are used to reinforce plastics in car interiors, creating components that are both lightweight and strong.

This reduces overall vehicle weight, leading to improved fuel efficiency and lower emissions, while promoting the use of renewable materials.

Bioplastics from renewable sources such as corn starch or agave are increasingly used, further lowering the carbon footprint of interior parts like wiring harnesses and containers.

Benefits of Natural Fiber Use

Natural fiber reinforcement reduces dependence on fossil-fuel-based plastics and supports a circular economy by utilizing renewable agricultural resources.

Innovative Exterior and Structural Materials

The automotive industry is embracing innovative materials to enhance sustainability in car exteriors and structures. These materials reduce weight and environmental impact while meeting safety standards.

Among these innovations, the use of cellulose from agricultural waste and recycled metals like steel and aluminum play a crucial role in creating eco-friendly vehicle bodies.

Cellulose from Agricultural Waste

Cellulose derived from agricultural byproducts is gaining attention as a sustainable replacement for traditional materials. It is stronger and lighter than steel, providing performance benefits.

This renewable resource reduces reliance on mining and lowers the carbon footprint in automotive manufacturing. Its integration supports circular economy principles.

Manufacturers experimenting with cellulose composites aim to create durable parts that contribute to overall vehicle weight reduction and fuel efficiency.

Recycled Metals: Steel and Aluminum

Recycling metals like steel and aluminum significantly decreases energy consumption compared to producing new metals from ore, reducing emissions in car production.

Using recycled metals helps lower resource extraction impacts and aligns with sustainability goals in the automotive supply chain.

This practice enables manufacturers to maintain material quality and safety while enhancing environmental responsibility.

Compliance with Regulatory Constraints

Innovative materials must comply with strict regulatory standards for safety, durability, and environmental impact, ensuring reliable vehicle performance.

Meeting these constraints challenges designers to balance sustainability with compliance, requiring ongoing research and development.

Collaboration with regulators promotes the adoption of green materials while safeguarding consumer protection and vehicle integrity.

Environmental and Economic Benefits

The adoption of sustainable materials in car manufacturing significantly reduces emissions and conserves resources. These materials help lower the environmental footprint across the vehicle’s lifecycle.

Besides environmental gains, sustainable materials can also impact costs and production processes, encouraging wider industry adoption and supporting a greener automotive sector.

Reducing Emissions and Resource Consumption

Incorporating materials like bioplastics, recycled metals, and natural fibers helps reduce greenhouse gas emissions by lowering fossil fuel dependency during production and vehicle operation.

Using lighter, renewable components decreases fuel consumption and minimizes resource extraction, promoting a more efficient and eco-friendly automotive industry.

These reductions contribute to climate goals and support the transition towards sustainable mobility solutions preferred by regulators and consumers alike.

Cost Implications and Industry Adoption

While some sustainable materials may initially increase production costs, their long-term savings from material efficiency and regulatory compliance are substantial.

Many leading manufacturers are already integrating these materials, leveraging economies of scale to make eco-friendly cars more affordable and accessible to a broader market.

Cost-effective implementation of green materials drives innovation and fosters a competitive, sustainable automotive sector aligned with environmental priorities.

Future Trends in Sustainable Car Manufacturing

The automotive industry is rapidly evolving, with leading manufacturers integrating sustainable materials to create greener vehicles. This shift reflects growing environmental awareness and technology advancement.

Future trends focus on increasing use of renewable, recycled, and innovative materials that improve vehicle efficiency, durability, and reduce carbon footprint throughout the car’s lifecycle.

Current Applications by Leading Manufacturers

Major automakers are already incorporating sustainable materials such as bioplastics, recycled metals, and natural fiber composites into new models, demonstrating commitment to environmental goals.

Examples include electric vehicles using lightweight interiors with synthetic leather alternatives and exteriors reinforced with cellulose-based components to enhance sustainability.

This proactive adoption drives industry standards forward and encourages global suppliers to prioritize eco-friendly materials in production chains.

Goals for an Efficient, Circular Automotive Sector

The industry’s primary goal is to establish a circular economy where materials are reused, recycled, and waste is minimized, ensuring long-term environmental and economic benefits.

Efficient resource management targets reduced emissions and lower energy consumption in manufacturing, supporting sustainable growth and regulatory compliance.

Automotive companies aim to develop fully recyclable vehicles and sustainable supply chains, promoting a resilient, eco-conscious sector that meets consumer and planetary needs.