Automation in Car Manufacturing

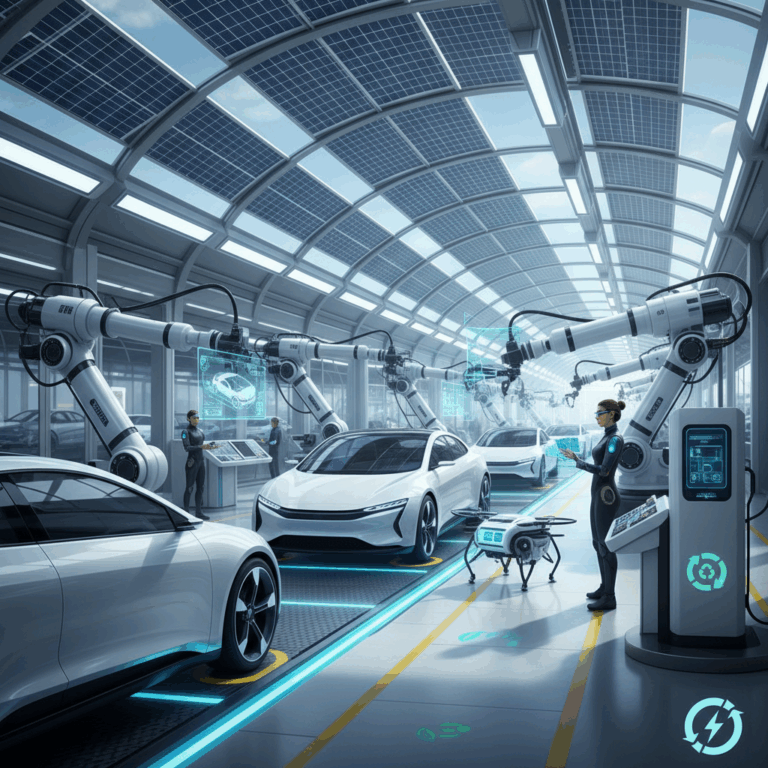

The automotive industry is rapidly evolving with automation at its core. Advanced technologies are transforming manufacturing processes for higher efficiency and precision.

Automation leverages cutting-edge tools like artificial intelligence and interconnected systems, enabling smarter and more streamlined production lines.

This shift promises significant productivity improvements while also reducing errors and operational downtime in car manufacturing.

Advanced Technologies Enabling Automation

Artificial intelligence and machine learning systems analyze data to optimize manufacturing workflows in real time. These technologies enable predictive maintenance and quality control.

The Internet of Things (IoT) connects machines and sensors, allowing seamless communication to monitor every production stage continuously.

Additionally, additive manufacturing and robotics automate complex tasks, increasing customization capabilities and production speed.

Through these technologies, the industry achieves greater flexibility and responsiveness to changing production demands and market trends.

Benefits of Intelligent Automation

Intelligent automation significantly reduces production downtime by diagnosing issues early and allowing prompt corrective actions. This boosts operational efficiency.

Automated processes enhance product quality by minimizing human errors, resulting in more consistent and reliable vehicles on the market.

Moreover, these systems improve safety by taking over hazardous tasks and creating a more controlled manufacturing environment.

Sustainability Trends in Automotive Production

The automotive industry is increasingly focused on sustainability, aiming to reduce environmental impact through innovative production methods. This shift responds to growing global environmental concerns.

Manufacturers are integrating sustainable practices by adopting electrification, recycled materials, and emission reduction strategies, aligning with regulatory demands and consumer expectations.

Sustainability in production not only benefits the environment but also drives technological advancements and market competitiveness in the automotive sector.

Electrification and Electric Vehicles

Electrification stands at the forefront of sustainable automotive trends, with electric vehicles (EVs) gaining rapid market acceptance worldwide. EVs offer reduced emissions and lower operating costs.

Advances in battery technology have improved EV range and charging times, making them more practical for everyday use. Manufacturers are expanding their EV portfolios to meet rising demand.

Government incentives and stricter emission regulations further encourage the shift toward electric mobility, pushing the industry to innovate and scale EV production.

Use of Recycled and Biocompatible Materials

Automakers are increasingly adopting recycled and biocompatible materials in vehicle production to minimize resource consumption and waste. These materials reduce the ecological footprint of manufacturing.

Recycled metals, plastics, and natural fibers replace traditional components without compromising vehicle performance or safety, supporting circular economy principles in the industry.

Biocompatible materials, sourced from renewable origins, contribute to sustainable vehicle interiors and reduce reliance on petroleum-based products.

Environmental Impact and Emission Reduction Goals

The industry aims to drastically cut carbon emissions and environmental impact through cleaner production processes and comprehensive lifecycle strategies. These goals align with international climate agreements.

Manufacturers implement energy-efficient manufacturing technologies and renewable power use to reduce operational emissions, enhancing overall sustainability.

Progress Towards Net-Zero Emissions

Many carmakers have committed to achieving net-zero emissions within the next few decades, integrating green manufacturing and sustainable supply chains to meet ambitious climate targets.

Digitalization and Connectivity in Future Vehicles

Digitalization revolutionizes vehicle development by integrating smart technologies, enhancing both production and user experience. Connectivity enables seamless communication within vehicle systems.

Future vehicles will not only be smarter but also interconnected, sharing data with other cars and infrastructure to improve safety, efficiency, and convenience in transport networks.

This digital transformation supports real-time decision-making, predictive maintenance, and personalized features, paving the way for a new automotive era.

Role of IoT in Vehicle and Manufacturing Processes

The Internet of Things (IoT) connects various vehicle components and manufacturing equipment, enabling continuous data exchange and real-time monitoring.

IoT enhances production efficiency by tracking performance, predicting maintenance needs, and ensuring quality control throughout the manufacturing lifecycle.

In vehicles, IoT powers smart features like diagnostics, adaptive systems, and personalized settings, improving driver experience and safety.

Such connectivity also supports vehicle-to-vehicle (V2V) communication, helping coordinate traffic and reduce accidents.

Autonomous Vehicles and Infrastructure Communication

Autonomous vehicles rely heavily on advanced communication networks to interact with road infrastructure, enhancing navigation and safety systems.

This communication allows vehicles to receive critical information like traffic signals, hazards, or road conditions, enabling smarter and more responsive driving decisions.

Integrating infrastructure communication supports optimal traffic management and reduces congestion, contributing to a smoother transport ecosystem.

Smart Cities and Connected Mobility

Connected autonomous vehicles are crucial for developing smart cities, where integrated transport systems optimize urban mobility and reduce environmental impact.

Through infrastructure communication, these vehicles contribute to data-driven urban planning and improved public transportation efficiency.

Industry Transformation and Market Adaptation

The automotive industry is undergoing profound transformation driven by technological advances and shifting market dynamics. Companies must adapt rapidly to remain competitive.

Innovation in manufacturing and strategic alignment with global demands are critical for sustainability and long-term growth in a complex regulatory environment.

Efficiency and Productivity Improvements

Enhancing efficiency is essential as carmakers adopt automation and digital tools to streamline production and reduce costs. Productivity gains support faster delivery and scalability.

Lean manufacturing techniques combined with real-time data analytics identify bottlenecks and optimize workflows, improving output without compromising quality.

Investment in employee training and flexible systems enables seamless adoption of new technologies, maintaining high performance during transitions.

Adapting to Global Market Demands and Regulations

The global automotive market requires agile adaptation to diverse regulations and consumer preferences across regions. Manufacturers respond by localizing production and customizing offerings.

Stricter emissions standards and safety regulations worldwide compel the industry to innovate continuously, integrating cleaner technologies and enhanced safety features.

Collaborative partnerships and global supply chain resilience support compliance and market responsiveness, ensuring manufacturers meet both regulatory and consumer expectations.